[rev_slider alias=”ppe-services-moderm”][/rev_slider]

The Covid-19 Pandemic Has Changed Our World; Delta and The Many Omicron Variants Reminds us to Stay Vigilant; The Marketplace has Taught us to Be Careful.

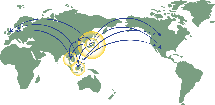

Personal Protective Equipment (PPE) is more prevalent than ever. Covid-19 (and its' many variants), has spread through our global population. Worker in law enforcement, first responders, correctional services, hospitals, retail stores, food services; EVERYBODY should get vaccinated & use PPE to keep us all safe. The market to supply PPE has evolved and we have waded through the mess. In the first wave, this spawned much fraudulent and "opportunistic" activity. Today, the market has learned from its' mistakes and is improving in many ways. How do buyers and sellers manage this changing marketplace? We help you understand all facets of the current and evolving PPE supply chain. Read on to discover how RiverPoint PPE can help your organization.

- Companies are trying to tap the lucrative pandemic PPE market. Financial companies have begun investing in domestic manufacturing initiatives to build up PPE manufacturing capabilities in-country. Many politicians back the creation of domestic PPE manufacturing, as the Covid 19 pandemic has spotlighted weaknesses in global supply chains and “strategic” PPE supplies are the soup-de-jour. Politicians are preaching more domestic manufacturing to sell job creation and incentivizing companies to build large domestic PPE manufacturing capabilities. Financiers are taking advantage of this as governments are handing out very generous terms (low or no) taxes, free land, low-cost financing, etc). We have worked with many domestic manufacturing companies but to turn this into a long-term opportunity, local governments need to support these businesses beyond just spoken words and unkept promises. Contact us for details on domestic manufacturing in your locale.

- Goods that importers have brought into the country and stored in warehouses from manufacturers abroad. They often sell at a higher cost because the goods are bought and stored domestically and can be delivered at a moment’s notice. Many legitimate wholesalers who ran out of inventory during the initial Covid waves have now restocked their supplies. Other companies have pivoted to PPE as these are the products buyers are needing most. "On-the-ground" (OTG) suppliers are only holding minimal inventory as when the market drops back to “normal” they do not want to be left holding expensive inventory. Anyone telling you they are holding millions of inventory is likely trying to deceive you. How do you know if distributors are really approved by brand owners to sell the PPE they have? Are these counterfeit or blackmarket goods (there were many cases of this during the pandemic)? How do you know who you can trust? How much is smoke and mirrors? Understand the evolving OTG goods marketplace before you dive in.

- Often the method of choice for most resellers, brands, and large corporations prior to the pandemic. A low-cost, high-quality, transparent supply chain that has not only been vetted but also proven over years of experience. Yes, there are many “fly-by-night” operations in this crazy marketplace (taking advantage of the FOMO furor over PPE). In the first Covid-19 wave, there are many cases of organizations rushing to procure medical supplies & PPE from “quick” sources; only to be disappointed with poor quality goods (or counterfeit goods), extremely high prices, and suppliers who knew next to nothing about PPE before the pandemic started. Many took large monetary deposits and disappeared. If you have a long-term supply plan, it makes sense to order factory direct but what supplier auditing is needed in order to trust that they can do what they are promising? What about logistics and import duties? What about quality control and product inspections? Offshore manufacturing is a fantastic option, if you know the right way to do it. Inquire about offshore manufacturing here.

Law Enforcement, Correctional Services, First Responders and Our Military

First Responders, Correctional Services, Military Personnel and Law Enforcement are put at risk everyday and while they are issued bullet proof vests, helmets, etc., the pandemic has exposed a need to protect them from viruses passed through droplets, blood, needles and other contaminants they may come into contact with in their work. PPE to protect them from Fentanyl and other illicit drugs passed thru dirty syringes and contact with blood and saliva. Top quality N95 masks and other more robust respirators, nitrile gloves that are tough enough to protect them and resistant to tearing punctures and needles. We need to protect our heroes, so they can continue to protect us.

Restaurants, Retail, Grocery and Gyms

The FDA is sharing has best practices to operate retail, grocery stores, restaurants, and associated pick-up and delivery services during the COVID-19 pandemic to safeguard workers and consumers. This list for employee health, cleaning and sanitizing, and personal protective equipment (PPE). Employees for this segment interact with the general population continually and it's important for employers to protect these workers.

High Quality Products from New PPE Brands

The global PPE market is fragmented with the presence of many small-and-medium-sized players, but the market is dominated by established manufacturers such as Cranberry and 3M. The market leaders prioritize product innovation by focusing on traditional R&D and investments but have high overhead and even higher pricing. Although the top vendors cater to larger customers; innovative and flexible newcomers are launching PPE at more competitive price points to gain market share. Several new entrants in the domestic PPE market (North America) are producing PPE that incorporates robotics, artificial intelligence and innovative new production methods.

PROCUREMENT BEGINS WITH TRUST

When procuring millions of dollars worth of PPE for government, hospitals, business and industry, there is a process involved. In working to get PPE to wherever it is needed, there is also a process. But it shouldn't be difficult or one-sided. If a potential supplier immediately talks about payment, deposits and especially, "proof of funds" before simple due diligence, sampling or other procurement processes, then this is probably a good sign of lack of trust. On the other hand, if the supplier is open with specifications and certifications, as well as samples, and the buyers are open about needs, timing, destination and and their organizational procurement requirements, this the hallmarks of building a line of open communication and building trust. Please contact us with your needs and then let's work through it together.